Berikut beberapa pilihan yang dapat digunakan untuk memroduksi komponen (

part). Pilihan proses

manufaktur berikut dapat diterapkan pada bahan logam maupun non logam.

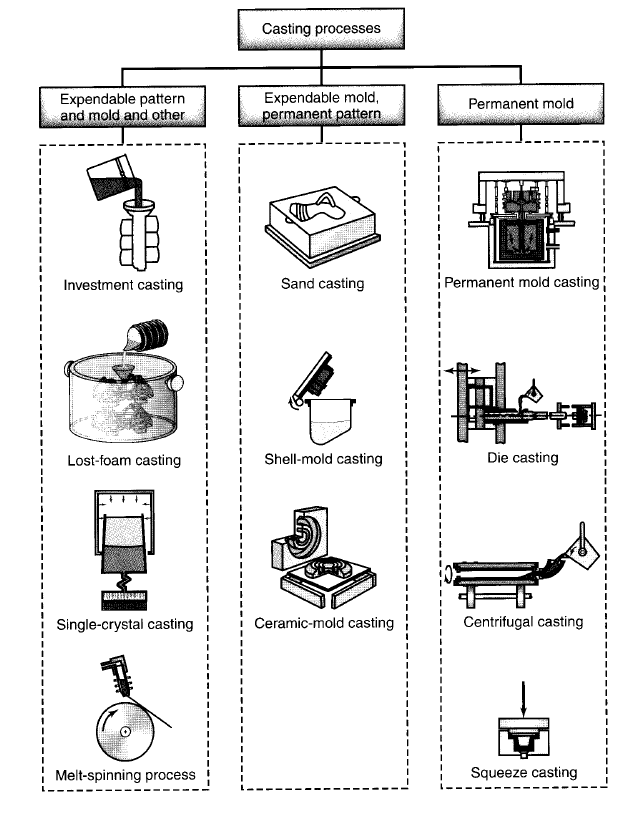

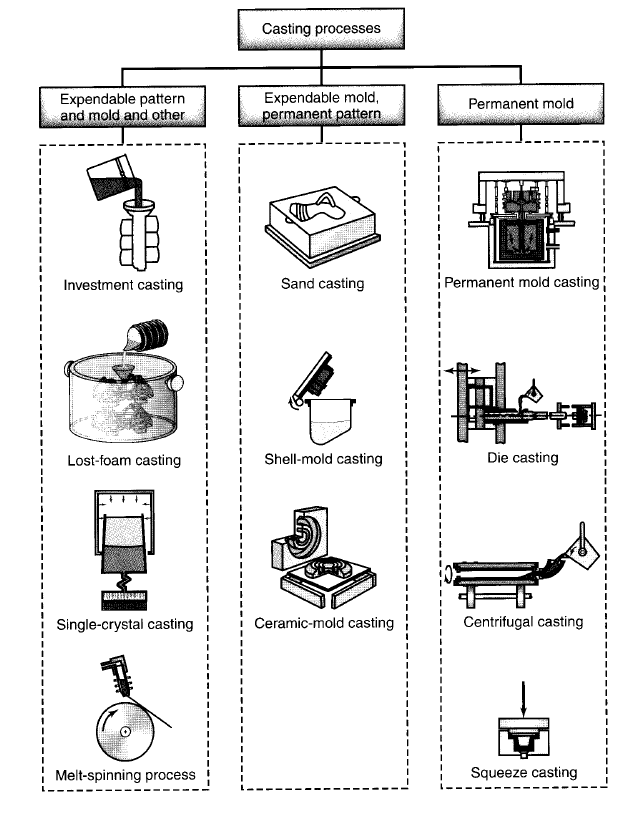

- Proses-proses pengecoran (casting).

|

Gambar 1. Macam-macam Proses Pengecoran.

(Sumber: S. Kalpakjian, S. R. Schmid, dan H. Musa, 2009, Manufacturing Engineering and Technology, 6th ed.)

|

- Proses-proses forming dan shaping. Forming dan shaping dibagi menjadi: proses bulk deformation dan proses sheet metal forming.

|

Gambar 2. Macam-macam Proses Bulk Deformation.

(Sumber: S. Kalpakjian, S. R. Schmid, dan H. Musa, 2009, Manufacturing Engineering and Technology, 6th ed.)

|

|

Gambar 3. Macam-macam Proses Sheet Metal Forming.

(Sumber: S. Kalpakjian, S. R. Schmid, dan H. Musa, 2009, Manufacturing Engineering and Technology, 6th ed.)

|

- Proses-proses pengolahan polymer.

|

Gambar 4. Macam-macam Proses Pengolahan Polymer.

(Sumber: S. Kalpakjian, S. R. Schmid, dan H. Musa, 2009, Manufacturing Engineering and Technology, 6th ed.)

|

|

Gambar 5. Macam-macam Proses Machining (Cutting).

(Sumber: S. Kalpakjian, S. R. Schmid, dan H. Musa, 2009, Manufacturing Engineering and Technology, 6th ed.)

|

|

Gambar 6. Macam-macam Proses Joining.

(Sumber: S. Kalpakjian, S. R. Schmid, dan H. Musa, 2009, Manufacturing Engineering and Technology, 6th ed.)

|

Referensi

S. Kalpakjian, S. R. Schmid, dan H. Musa, 2009,

Manufacturing Engineering and Technology, edisi 6.